Design Process

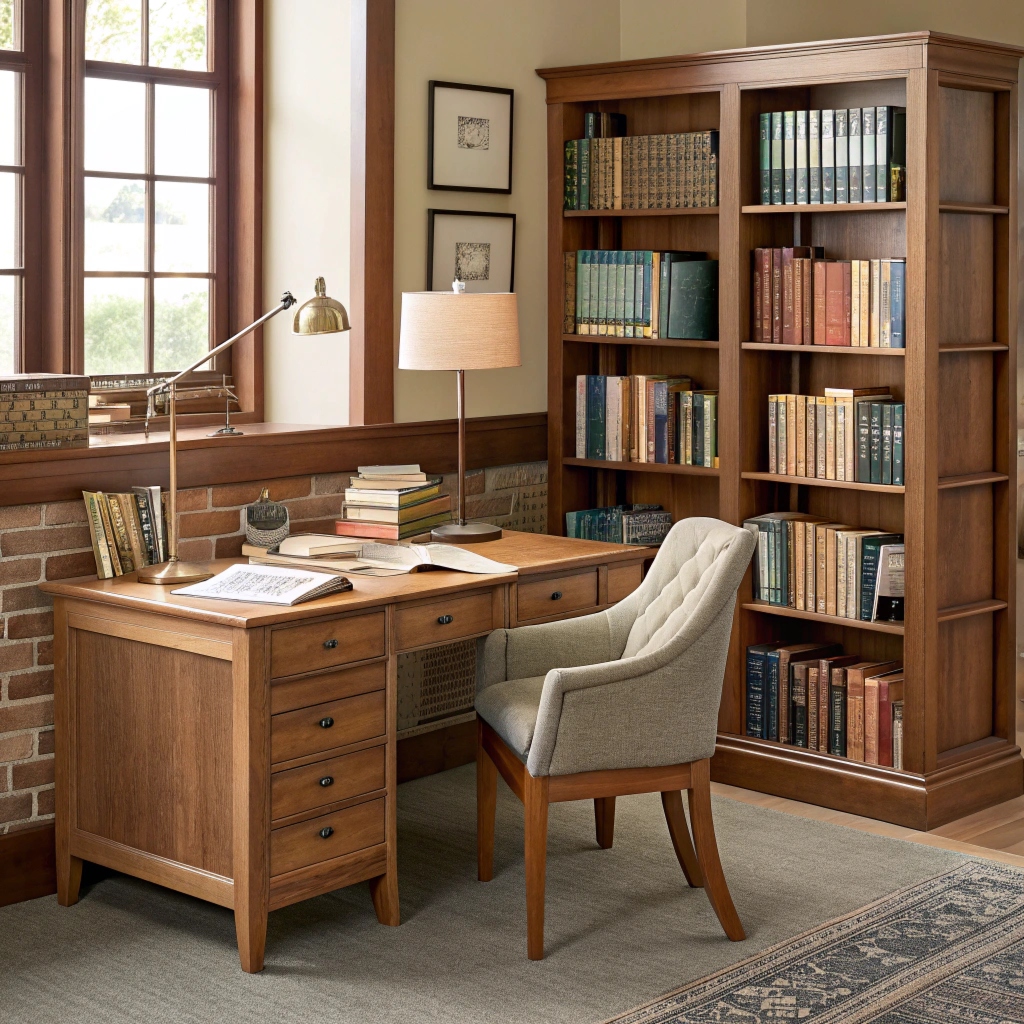

The development of bespoke furniture from initial concept through to completion.

Initial Discussion

The process begins with understanding the client's requirements, the architectural context, and the functional needs of the piece. Discussions cover the intended use, aesthetic preferences, material considerations, and any constraints imposed by the space.

Site visits may be conducted to assess the space, measure dimensions, and understand the relationship between the proposed furniture and its surroundings. Photographs and drawings of the space help inform the design development.

Design Development

Design development involves sketching, technical drawing, and material selection. Initial sketches explore form, proportion, and layout options. These are refined through discussion and iteration.

Technical drawings are produced to specify dimensions, materials, and construction methods. These drawings serve as the basis for making and ensure that the piece will function as intended and fit within its space.

Material samples are reviewed to confirm selection and to understand how materials will appear in the finished piece. Samples may be viewed in the intended location to assess colour and texture in context.

Approval and Refinement

Design proposals are presented to the client for review. Drawings, samples, and descriptions communicate the proposed approach. Feedback is incorporated into refinements before final approval.

Once approved, detailed joinery drawings are prepared. These specify all dimensions, joint types, material thicknesses, and construction details. The drawings guide the making process and ensure consistency and accuracy.

Material Selection and Preparation

Timber is selected from stock or ordered to specification. Boards are chosen for colour, grain pattern, and figure, with consideration given to how they will appear in the finished piece.

Materials are prepared for use, including milling to size, jointing edges, and preparing surfaces. The preparation stage ensures that materials are ready for the construction phase and that dimensions are accurate.

Construction

Construction begins with the preparation of components. Joints are marked and cut, surfaces are prepared, and elements are fitted together. The process follows the technical drawings while allowing for adjustments based on the material's characteristics.

Assembly proceeds systematically, with dry-fitting to check fit and alignment before final assembly. Glue, screws, or other fasteners are used as specified, with care taken to ensure strong, accurate connections.

The relationship between design and making is continuous. Adjustments may be made during construction as the material reveals its characteristics or as the piece develops. This flexibility is part of the bespoke process.

Finishing

Once construction is complete, surfaces are prepared for finishing. This involves planing, scraping, and sanding to achieve the desired smoothness and texture. Hand-finishing techniques are used to refine surfaces and remove machine marks.

The finish is applied in stages, with each coat allowed to cure before the next is applied. The finish protects the wood while enhancing its natural appearance, contributing to the piece's overall character.

Installation

For built-in furniture or pieces that must fit precisely within a space, installation is carried out on site. The piece is delivered and positioned, with final adjustments made to ensure proper fit and alignment.

Hardware is fitted, drawers and doors are adjusted for smooth operation, and any final details are completed. The piece is inspected to ensure it meets the design intent and functions as intended.

Client Collaboration

The design process is collaborative, with regular communication between client and maker. Initial discussions establish requirements, and design development involves feedback and refinement.

This collaborative approach ensures that the final piece meets the client's vision while benefiting from the maker's expertise in materials and construction.

Technical Drawings

Detailed technical drawings specify all dimensions, materials, and construction methods. These drawings serve as the basis for making and ensure accuracy throughout the construction process.

The drawings include joinery details, material specifications, and assembly instructions, providing a complete guide for construction.